Composition of medical wastewater:

Wastewater in clinics includes 2 types:

Domestic wastewater from patients, relatives and employees.

The wastewater from the clinic includes: fluids, blood, E. coli, chemicals used for testing, sterilization, cleansing, vaccines, coliform, salmonella, shigella and Vibrio cholera, suspended solids, cadmium, lead, cadmium, zinc, phenols, organic substances, animal and vegetable grease, chemical waste, chemical solvents, and especially antibiotic residues.

Most of the medical wastewater is contaminated with microorganisms, so it is necessary to treat it before leaving the environment to avoid contamination affecting the community.

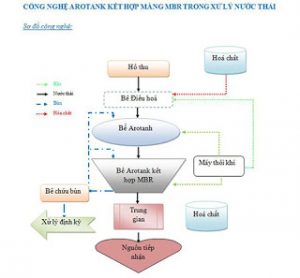

Technology demonstration:

|

| Aerotank technology incorporates MBR membrane |

Waste treatment clinics, dental clinics, disposable after use for purposes such as:

All wastewater is collected collectively into a general collection point and then pumped into the air conditioning tank.

Air conditioners regulate the flow and concentration of wastewater. With unstable flow characteristics during the operation of the clinic, stable flow regulation is essential for the microbiological system during wastewater treatment.

After the process of regulating the concentration and flow, wastewater flows through the Aerotank tank combining the MBR membrane. In Aerotank, waste water is mixed with aerobic microorganisms through an air supply system. This process facilitates the growth and development of aerobic microorganisms. During the exposure, aerobic microorganisms collect pollutants in waste water (CODs, BODs, nitrogen, phosphorus, heavy metals, etc.) as feeds, increase biomass and muddy cotton

Here under the influence of aerobic organisms, and the gas distribution system in the tank of COD, BOD is effectively treated 85-90% increase the water dissolved oxygen (DO). The level of DO in the Aerotank tank is always 1.5 – 2 mg / l.

Waste water treatment technology using MBR membrane is modern technology and is widely used in medical wastewater treatment today for its outstanding advantages.

MBR technology is a combination of both biological and physical methods. Each MBR unit is composed of several hollow fibers bonded to each other, each hollow fiber structured like a membrane with very small filter holes that some microbes are unable to penetrate. These MBR units will bind together into larger modules and place them in the treatment tanks.

Microbial activity in MBR technology is similar to aerobic activated sludge but instead of separating sludge with sedimentation technology, MBR technology is separated by membrane.

Since the size of the MBR membrane is very small (0.01 ~ 0.2 μm), the biological sludge will be kept in the tank, with high microbial density and increased processing efficiency. Clean water will be siphoned into the reservoir and escaped without going through the settling tank, filtering and disinfection.

|

| MBR membrane |

The wastewater after filtration from the MBR membrane meets QCVN 28: 2010 / BTNMT Column B.

During treatment, the treated water is often reused for automatic backwashing to prevent clogging of the activated sludge from the membrane wall.